Dry Room Design

Scientific Climate Systems has over 50 years of experience in designing and constructing dry rooms with the highest standards in mind. We begin with the initial consultation with the customer to understand the scope of the project installation of the dry room. Once this has been finalized, our team then moves to design the dry room to the customer's specifications along with additional considerations.

- Custom Built IDS Desiccant Dehumidification Unit, complete with integral controls, process air humidity extraction, reactivation air system, make-up air and moisture-laden heated exhaust air.

- Supply and Return Air Duct tightly sealed and insulated to prevent moisture migration and thermal loss.

- Make-up Air Ducts, to provide fresh air to room, for personnel, positive pressure, and to overcome owners' equipment exhaust.

- Exhaust Air Duct, to remove hot moisture-laden air from desiccant dehumidification.

- Modular Wall System with airtight seals, fire retardant construction, metal facing on both sides of insulation to prevent moisture migration into the dry room. Custom colors are available.

- Airlocks for normal personnel and equipment entry.

- Heat Rejection Unit or Condensing Unit used to remove dehumidifier heat gain as well as owner equipment heat loss, people, lighting and make-up air heat loads. These units can be installed outside of the building for efficiency.

Where to Install the Dry Room Dehumidification and Mechanical Equipment?

There are many optional locations for the Dehumidification and Mechanical Equipment. To minimize ducting runs, the equipment should be located within 50’ of Dry Room enclosure. The typical location is outdoors on an equipment pad or on the roof above. Other options are mounting the equipment within the building near the dry room or on a mezzanine if space is available. More remote locations beyond 50’ can be accommodated by larger duct size to reduce static losses or booster fans.

Custom Dry Room Lead Time

Standard lead times vary by the size and internal load profile of the Dry Room. Once a purchase order is issued, design drawings are generated and submitted for approval and release for manufacturing. Approval drawings take 3-4 weeks for submittal. Upon customer’s approval the following standard lead times apply:

- Dry rooms less than 100 square feet – 12-14 weeks after approval/release

- Dry rooms of greater than 1000 square feet to 5000 square – 14-16 weeks after approval/release

- Dry rooms greater than 5000 square feet to 10,000 square feet – 16-20 weeks after approval/release

- Dry rooms above 10,000 square feet – 20-26 weeks after approval/release

For critical applications, expedited delivery can be accommodated. These same high standards are also applied with our environmental test chambers.

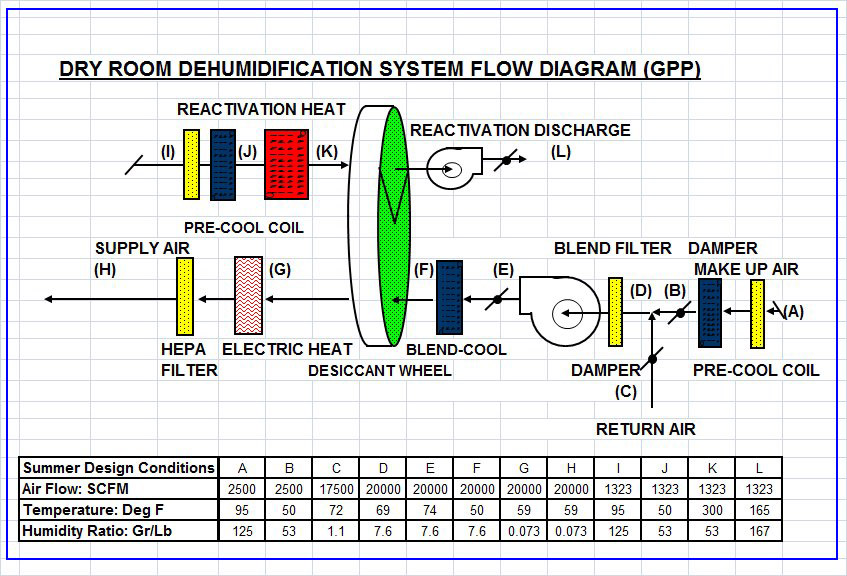

Dry Room Air Flow Chart

This Dehumidification Flow Diagram represents the latest technology available to condition and maintain extremely low dew point dry rooms for Lithium Battery process applications. SCS constantly evaluates vendors to select the most energy efficient performance based designs to provide long term operation reliability. This design offers low maintenance for cost effective monitoring and servicing.

Click here to submit a Request for Quote

Or call us today at 800-840-5778.